Read how inventors are working to create a sustainable economy by using our waste mountain to produce renewable raw materials.

Willem Sederel's friends describe him as ‘a hard-working, passionate businessman with an inquisitive mind and a talent for analysing problems quickly’. Even though he has now officially retired, he still works 40 to 50 hours a week. “I’m still looking for a better work-life balance; I want to spend more time with my family and my grandchildren. And accompany my wife on visits to our favourite museums more often.” Such as De Pont in Tilburg. “They always put on wonderful exhibitions.”

Willem worked in the petrochemical industry for 36 years. His employers were international companies that produced plastics for a seemingly infinite number of applications. For the packaging industry, for example, but also for more utilitarian products such as helmets and car parts. He is one of the initiators of the Green Chemistry Campus in Bergen op Zoom. The campus is a place where sustainable businesses work in open innovation on developments in green chemistry in preparation for the transition to a sustainable economy. What inspired a son of the oil industry to switch his focus to the bio-based economy?

A chemistry teacher called Van Woerkom awakened Willem Sederel's love of this branch of science. “He told captivating stories. About the surprising results of chemical experiments, or about how certain materials could be made. Chemistry affects all areas of your life, although you may not know it.” After gaining a degree in chemistry (as you would expect), he worked for Shell Research initially before accepting a position as a product developer at General Electric in Bergen op Zoom.

“My time at GE Plastics was a fantastic experience. I learned a great deal.” In 2007, GE was acquired by SABIC, a Saudi Arabian company. As the Innovation Manager for Plastics, Willem was involved in developing the CD, the DVD and polycarbonate, an extremely hard and tough plastic. “We even sent polycarbonate to the moon! The astronauts’ helmets were made from this material.”

Willem Sederel knows at first hand that innovation is a difficult process to manage. Five out every ten innovative ideas that make it to the experimentation stage never actually reach production. “Even so, innovations in chemistry can be true game changers that have a worldwide impact, on the environment for example. Sustainability is such an important topic: we have a duty to leave a healthy planet behind for future generations. The world is not in very good shape at the moment, but I am optimistic. We now have the ability to tackle specific problems.” Willem also wants to accomplish this mission for his six grandchildren. He calls himself a hands-on grandfather. “Romping around, reading out stories… but I also like to teach them things. When I tell them that I have been to the port of Rotterdam, they hang on my every word.”

His interest in sustainable and renewable raw materials dates back to about 2003. Customers were demanding non-fossil materials because consumers wanted more sustainable products. Scandinavia in particular had made significant advances in this area. “There was clear demand, so success was guaranteed.” Together with customers, GE Plastics analysed life cycles and calculated CO2 footprints. Oil was no longer an automatic choice as a raw material. “This was a completely different playing field. The products we could make from plant-based material were totally different because they were naturally antibacterial or had a better oxygen barrier.”

The first ideas for the Green Chemistry Campus (GCC) emerged in 2009. The Regionale Ontwikkelingsmaatschappij West Brabant (REWIN) put the following question to companies in West Brabant and Zeeland: Is your waste a suitable raw material for your neighbour? SABIC was also involved. Willem: “The result was that approximately half of those companies wrote a joint agenda, which we presented to the top industrial sectors. The theme was: Agro Meets Chemistry.”

The companies wanted a facility where innovative, bio-based products could be developed. And that facility was created on SABIC's site in Bergen op Zoom. A self-contained building that was perfect for the task. “We obtained approval from Riyad, the highest level within SABIC's management structure. The building now houses the GCC’s Campus Innovation Center.” The Provincial Authority of North Brabant, REWIN and the municipality of Bergen op Zoom are partners in this initiative. The Green Chemistry Campus was home to 3 companies when it started in 2011. That number has now grown to 11; all young technology companies that focus on bio-based techniques.

The ideas that the companies at the GCC come up with and turn into products will act as an innovation engine for the SME sector. Which, in turn, will force larger companies to go green and ensure an irreversible transition to a bio-based economy: a circular economy based on waste products and biomass. Willem: “Sustainability is not only a global theme, it is also very personal. Your personal choices and behaviour have an effect. As a result, I and my wife have consciously decided to become flexitarians. And, when we travel to Germany, we take the train instead of flying.”

The transition to a green economy is not optional he says, and will cause chaos initially. “We need to develop a different way of thinking and attach less importance to owning things.” He laughs: “I already share my sailing boat with a group of young sailors at my club. Great fun. You learn so much from young people!”

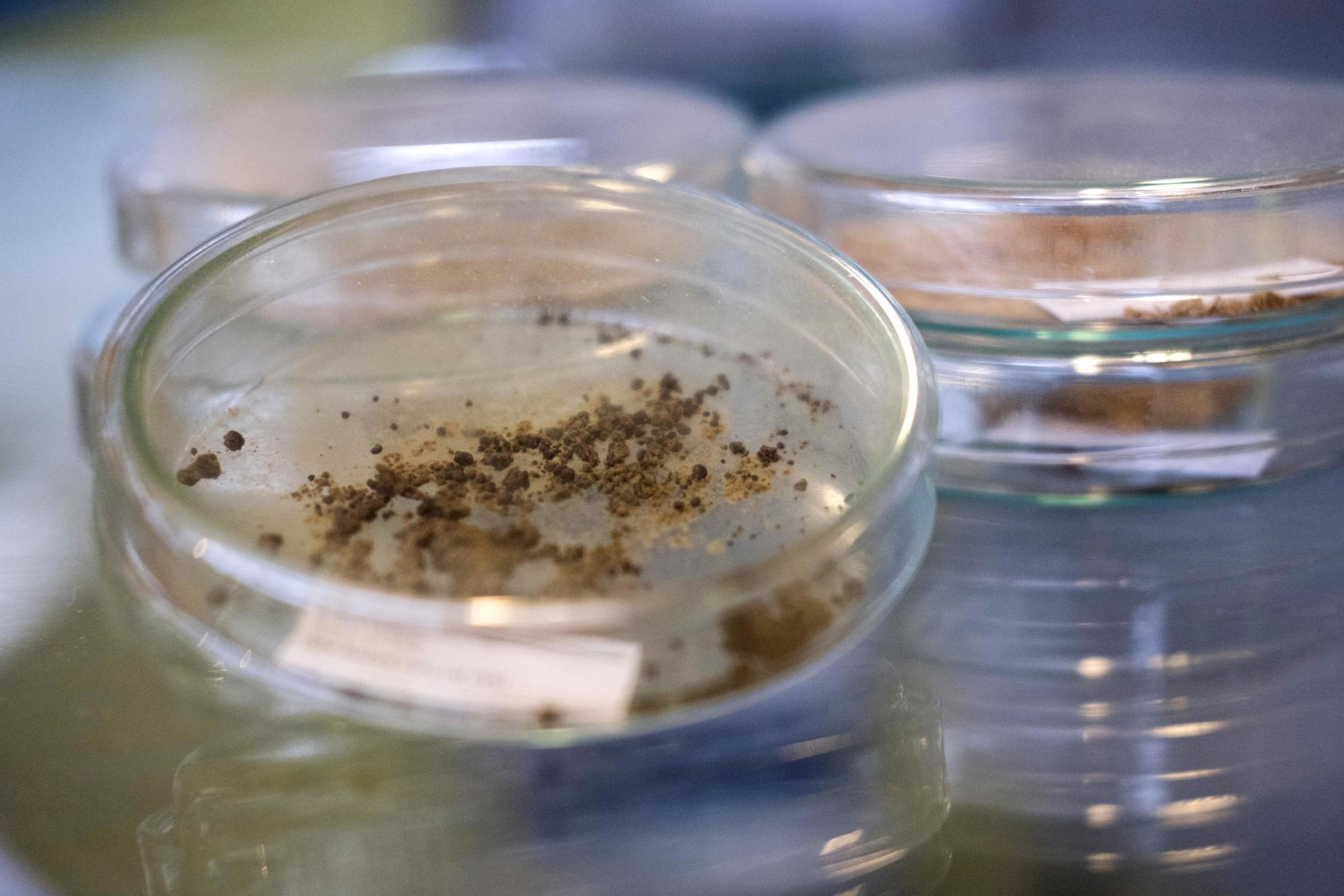

Willem Sederel is convinced of the GCC's commercial potential: “Many of the companies there will create jobs in the region. And a few, such as Biorizon and NNRGY Crops, are true game changers.” NNRGY Crops makes environmentally friendly paper, bio-plastic and building materials from elephant grass, a fast-growing plant. Biorizon is developing a production process for producing bio-aromatics from plant waste. Bio-aromatics are used to make paint and cosmetics. Both companies intend to build factories in the near future. Willem Sederel: “In 2025, my children and grandchildren will buy products that were invented at the Green Chemistry Campus, just wait and see!”

Petra Koenders, the director of the Green Chemistry Campus: “Construction work for our demo facility, which includes labs for process and product experiments, started early in 2018. New companies will move into the building in the summer of 2018. The GCC offers rented lab facilities and workspaces to companies that want to scale up their bio-based innovations. And we also provide support in the area of finance, marketing and business administration. We aim to create connections between more companies to stimulate cross-pollination. Another advantage of the site in Bergen op Zoom is that many farming companies - suppliers of biomass - are located in the area.

You can copy the full text of this story for free at the touch of a button